330102-00-90-50-01-05

Release time:2025-06-04

¥:Contact me for an offer Email:sales@xmjzjsgs.com

- Item No.:8210

- Brand:330102 Series

- Warranty Period: One Year Warranty

- Is brand new:Brand New

- Place of origin:USA

- Courier partners:DHL, UPS, TNT, FedEx and EMS.

- Payment Methods:T/T, PayPal, Western Union

- Whether it is in stock:Spot

- Evaluation:No comment

Product details

| Company Information | 330102-00-90-50-01-05 | ||

| sales@xmjzjsgs.com | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 903, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | ||

| TAGS |

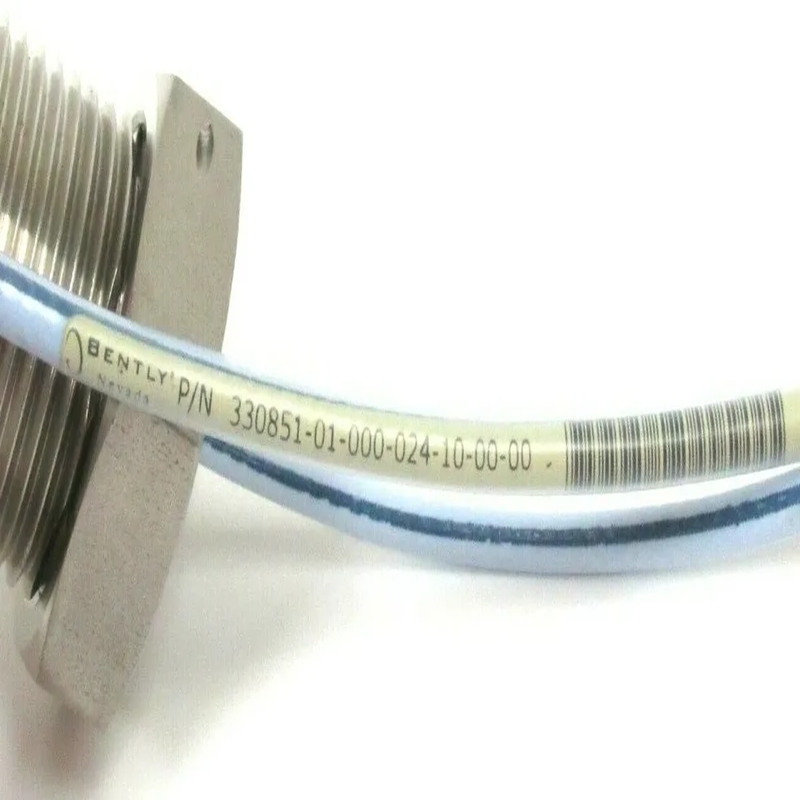

Bently Nevada 300102 Series Product Overview

The Bently Nevada 300102 series is a non-contact eddy current sensor probe, part of Bently Nevada's 3300 XL series, designed for high-precision shaft vibration and displacement measurement. This series is widely used for monitoring the health and performance of rotating machinery, such as turbines, compressors, motors, pumps, and fans.

Engineered for harsh industrial environments, the 300102 series features high accuracy, strong resistance to electromagnetic interference, durability, and long-term stability. It is widely applied in industries such as power generation, petrochemical, steel manufacturing, pulp & paper, and aerospace.

Bently Nevada 300102 Series Technical Specifications

| Specification | Details |

|---|---|

| Brand | Bently Nevada (GE) |

| Series | 3300 XL Series |

| Model | 300102 |

| Measurement Type | Non-contact eddy current measurement |

| Measurement Object | Shaft vibration, shaft displacement, keyphasor |

| Probe Diameter | 5mm, 8mm, 11mm (varies by model) |

| Cable Length | 0.5m, 1m, 5m, 9m (options available) |

| Output Signal | 4-20mA, BNC connector |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -50°C to +200°C |

| Material | 316L Stainless Steel |

| Ingress Protection | IP67 (Waterproof & Dustproof) |

| Weight | Approx. 250g (varies with cable length) |

| Mounting Method | Threaded Mount (M6, M8, M10 options) |

| Certifications | CE, ATEX, UL |

Key Features of Bently Nevada 300102 Series

- High-Precision Measurement: Utilizes non-contact eddy current technology to provide nano-level precision in vibration and displacement monitoring.

- Wide Temperature Range: Operates effectively between -35°C to +177°C, suitable for extreme industrial conditions.

- Excellent Electromagnetic Resistance: Optimized shielding ensures stable signal transmission with minimal interference.

- Rugged and Durable: Constructed with 316L stainless steel, rated IP67 for waterproof and dustproof protection.

- Multiple Cable Lengths Available: Options include 0.5m, 1m, 5m, and 9m, catering to different installation needs.

- Seamless System Integration: Fully compatible with 3300 XL Proximity Transducers and Bently Nevada 3500 Monitoring System for real-time diagnostics.

Applications of Bently Nevada 300102 Series

Bently Nevada 300102 series is widely used for monitoring rotating machinery in various industries:

- Turbines: Measures shaft vibration and displacement in real time to prevent excessive wear and failures.

- Compressors: Detects bearing wear and imbalance for early fault detection and predictive maintenance.

- Pumps & Fans: Monitors vibration levels to prevent downtime caused by misalignment or impeller damage.

- Generators & Motors: Provides continuous monitoring to prevent overheating or mechanical failure.

- Petrochemical Equipment: Ensures the stable operation of critical machines like centrifuges and mixers, reducing maintenance costs.

Related Models & Alternatives

Here are similar or alternative models within the Bently Nevada 300102 series, each designed for specific applications:

| Model | Key Features | Application |

|---|---|---|

| 300103 | Similar to 300102 but with a larger probe diameter | Turbines, Compressors |

| 300104 | Longer cable length (up to 15m) for remote sensing | Remote bearing vibration monitoring |

| 330130 | Designed for high-temperature environments (up to 200°C) | Boilers, Gas Turbines |

| 330180 | Compact size for small machinery, higher precision | Small motors, compact pump systems |

| 330400 | Optimized for fans and cooling towers | HVAC systems, Cooling Towers |

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the Bently Nevada 300102 probe?

A1: The 300102 probe is a non-contact eddy current sensor designed for measuring shaft vibration, displacement, and keyphasor signals in rotating machinery.

Q2: What cable lengths are available for the 300102 series?

A2: The probe comes in 0.5m, 1m, 5m, and 9m cable lengths to fit different installation requirements.

Q3: Can the 300102 probe withstand high temperatures?

A3: Yes, it operates in environments from -35°C to +177°C, and its storage temperature is rated up to 200°C.

Q4: Is the 300102 probe compatible with Bently Nevada 3500 monitoring systems?

A4: Yes, it is fully compatible with 3300 XL Proximity Transducers and Bently Nevada 3500 Monitoring System.

Q5: How is the 300102 probe installed?

A5: It is installed using a threaded mounting system, available in M6, M8, and M10 configurations.

Q6: What is the ingress protection (IP) rating of the 300102 probe?

A6: The probe is IP67-rated, making it waterproof and dustproof for harsh environments.

Q7: What is the measurement accuracy of the 300102 probe?

A7: The 300102 provides nano-level precision using eddy current sensing technology.

Q8: What signals does the 300102 probe measure?

A8: It measures shaft vibration, shaft displacement, and keyphasor signals.

Q9: What industries typically use the 300102 probe?

A9: It is widely used in power generation, petrochemical, steel manufacturing, aerospace, and pulp & paper industries.

Q10: How does the 300102 probe connect to a monitoring system?

A10: It connects via a BNC connector or 4-20mA output, allowing easy integration with existing monitoring systems.

Marketing Advertisements for Bently Nevada 300102 Series

1. "Precision Vibration Monitoring – Bently Nevada 300102"

Enhance your rotating machinery performance with the Bently Nevada 300102 eddy current probe. Designed for high-accuracy vibration and displacement measurement, this probe ensures real-time monitoring and prevents costly downtime. With IP67 protection and 316L stainless steel housing, it thrives in harsh environments. Upgrade to Bently Nevada's precision engineering today!

2. "Reliable Performance, Unmatched Accuracy – 300102 Series"

The Bently Nevada 300102 delivers nano-level accuracy with a wide operating range (-35°C to +177°C). Its robust design and superior electromagnetic resistance make it the ideal solution for turbines, compressors, and industrial motors. Experience the future of industrial monitoring with Bently Nevada 300102!

3. "Maximize Machine Uptime with Bently Nevada 300102"

Downtime is expensive. The Bently Nevada 300102 ensures continuous machine monitoring, reducing unexpected failures and maintenance costs. With advanced non-contact eddy current technology, it provides unparalleled precision and durability. Keep your machinery running at peak performance with Bently Nevada!

4. "Bently Nevada 300102 – The Trusted Choice for Industrial Monitoring"

Trusted by leading industries worldwide, the 300102 probe delivers high-performance vibration and displacement monitoring. Its IP67 rating, rugged design, and multiple cable length options make it perfect for any challenging industrial setting. Optimize your machine reliability today!