Product details

| Company Information | 330101-00-32-10-02-05 | ||

| sales@xmjzjsgs.com | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 903, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | ||

| TAGS |

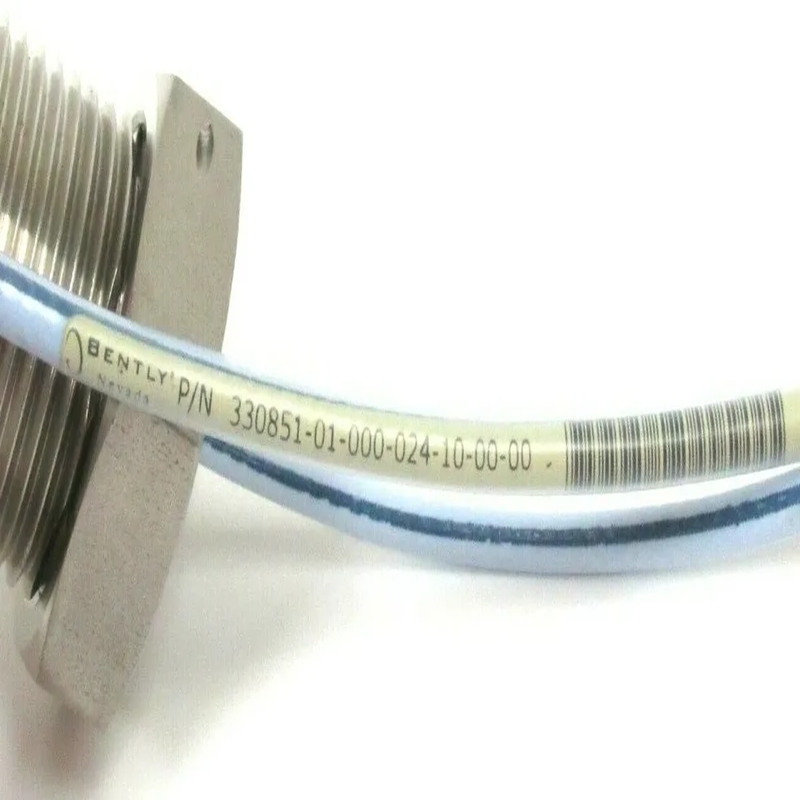

Bently Nevada 330101 Series Overview

The Bently Nevada 330101 Series is a part of the renowned 3300 XL Proximity Transducer System, specifically designed to measure shaft vibration, position, and phase reference in rotating machinery. Known for its accuracy, reliability, and rugged design, the 330101 series is widely used in critical machinery protection and condition monitoring applications across industries such as oil & gas, petrochemical, power generation, steel, and marine.

The 330101 Series is typically composed of a proximity probe, extension cable, and proximitor sensor, and it is fully compliant with API 670 standards, making it an industry standard in proximity sensing.

Bently Nevada 330101 Series Technical Specifications

| Specification | Details |

|---|---|

| Brand | Bently Nevada (GE) |

| Series | 330101 Series |

| System | 3300 XL Proximity Transducer System |

| Application | Vibration, Displacement, and Phase Reference |

| Measurement Range | 0 to 80 mils (0 to 2 mm) |

| Linear Range | 80 mils (2.0 mm) |

| Output Voltage | -200 mV/mil (-7.87 mV/µm) |

| Probe Tip Diameter | 5 mm or 8 mm options |

| Extension Cable Lengths | 5, 7, or 9 meters (standard) |

| Frequency Response | DC to 10 kHz (typical) |

| Target Material | 4140 steel (calibrated); also works on other metals |

| Environmental Protection | IP66 (probe and cable assemblies) |

| Operating Temperature | -35°C to +120°C (probe); -35°C to +85°C (cable) |

| Compliance | API 670 |

| Mounting Thread Options | 1/4-28 UNF, M8x1, and others |

| Dimensions (Typical Probe) | Length: 76 mm; Tip diameter: 5 mm |

| Weight (Typical Assembly) | ~0.5 to 1.0 kg depending on length and components |

Key Features of Bently Nevada 330101 Series

-

High Accuracy & Repeatability – Delivers highly accurate shaft position and vibration measurements for protection and diagnostics.

-

API 670 Compliant – Fully compliant with API 670 standards, ensuring its suitability for critical machine protection.

-

Robust Construction – Engineered for harsh environments, with IP66 protection and industrial-grade materials.

-

Wide Range of Configurations – Available in multiple lengths, thread types, and connector styles to suit various machine geometries.

-

System Integration Ready – Designed for seamless use with Bently Nevada’s 3300 XL and 3500 systems.

-

Superior Frequency Response – Suitable for high-speed rotating equipment requiring fast response and accurate phase detection.

Applications of Bently Nevada 330101 Series

The 330101 Series is designed for use in:

- Steam & Gas Turbines – Monitoring shaft vibration and rotor position.

- Centrifugal Compressors – Shaft displacement and phase reference.

- Pumps & Motors – Bearing and shaft monitoring.

- Gearboxes – Detecting shaft movement, unbalance, and misalignment.

- Blowers & Fans – Vibration monitoring in high-speed rotating equipment.

- Industrial Marine Engines – Vibration and positional tracking for maintenance and diagnostics.

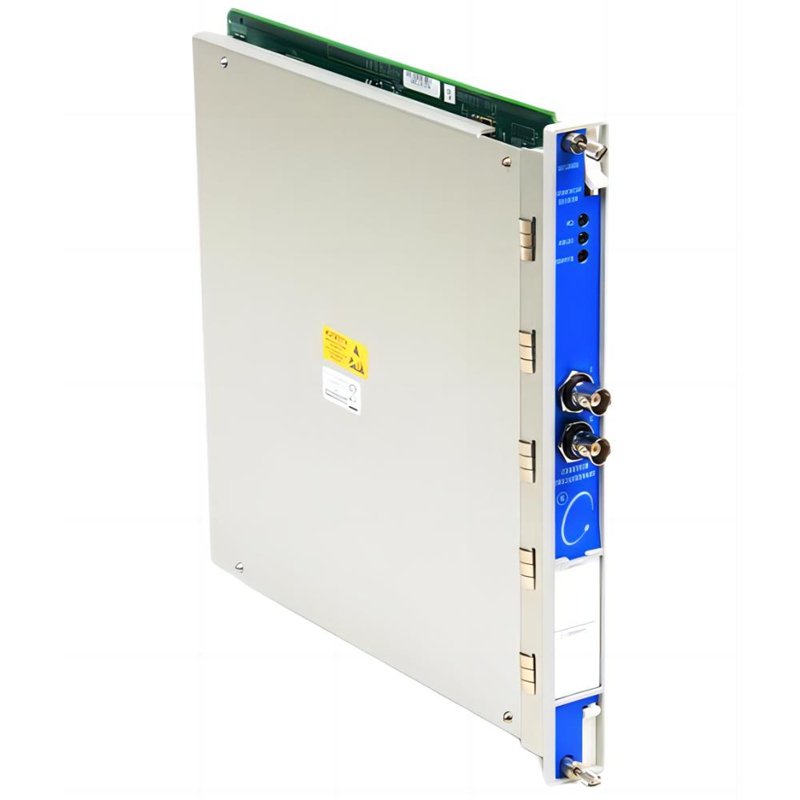

Related Models within the 3300 XL Series

| Model | Function | Output | Typical Application |

|---|---|---|---|

| 330101 | Proximity Probe (5 mm/8 mm tip) | -200 mV/mil | Shaft vibration/position monitoring |

| 330102 | High-temperature probe variant | -200 mV/mil | High-temp turbine monitoring |

| 330103 | Reverse mount probe | -200 mV/mil | Difficult-access equipment |

| 330130 | Extension cable | N/A | Connects probe to proximitor |

| 330180 | Proximitor Sensor | Signal conditioning | Interfaces probe with monitoring system |

Frequently Asked Questions (FAQs)

Q1: What does the Bently Nevada 330101 Series measure?

A1: It measures shaft vibration, axial position, and phase reference in rotating machinery using a non-contact eddy-current sensing method.

Q2: What is the output signal of the 330101 probe?

A2: The output is -200 mV/mil or approximately -7.87 mV/µm, which is industry standard.

Q3: Is the 330101 probe API 670 compliant?

A3: Yes, it is fully compliant with API 670, which is the standard for machinery protection systems.

Q4: What systems is the 330101 compatible with?

A4: It works seamlessly with 3300 XL, 3500 Series, and other Bently Nevada condition monitoring systems.

Q5: Can the 330101 be used in high-temperature applications?

A5: For high-temperature environments, it's better to use the 330102 high-temp version.

Q6: What lengths are available for the extension cable?

A6: Standard lengths include 5 m, 7 m, and 9 m, but custom lengths may be available.

Q7: Can I mount the 330101 in tight spaces?

A7: Yes, with multiple thread options and reverse-mount versions, it is suitable for compact or complex machine layouts.

Q8: What is the tip diameter of the 330101 probe?

A8: It comes in 5 mm or 8 mm tip diameters, depending on the application and clearance.

Q9: Is the probe resistant to oil and water ingress?

A9: Yes, the probe and cable assemblies are IP66 rated, suitable for industrial conditions.

Q10: What materials does the 330101 calibrate to?

A10: It is factory-calibrated to 4140 steel, but it can also be used on other conductive metals with minor calibration adjustments.

Marketing Advertisements for Bently Nevada 330101 Series

1. "Precision You Can Trust – Bently Nevada 330101"

Built for the most demanding environments, the 330101 proximity probe delivers high-precision vibration and displacement monitoring trusted by engineers worldwide.

2. "Measure the Unseen – 330101 Series"

Detect early signs of machinery wear and avoid catastrophic failure with the 330101 Proximity Sensor. Ideal for turbines, compressors, and more.

3. "Your First Line of Defense in Machine Protection"

The 330101 Series ensures accurate shaft monitoring, helping you prevent downtime and increase equipment life. A must-have for serious reliability teams.

4. "API 670 Compliant. Plant-Wide Ready."

Engineered to meet API 670 standards, the Bently Nevada 330101 Series is your go-to solution for precision and compliance in critical asset monitoring.